Effective Ways to Solder Wires in 2025: A Comprehensive Guide for Better Connections

Soldering wires is a crucial skill for anyone interested in electronics, DIY projects, or crafting. Understanding how to solder effectively can lead to stronger connections, long-lasting repairs, and enhanced success in various soldering projects. This guide is tailored to help both beginners and advanced users learn effective soldering techniques, tools, and safety tips. In the following sections, we will detail how to properly solder wires, the essential soldering equipment, and step-by-step instructions for creating stable and reliable connections.

We’ll explore basic soldering principles, share expert recommendations, and cover common soldering mistakes to avoid. As you progress, you’ll also find useful insights into more advanced soldering methods and tools. So whether you’re just getting started or looking to sharpen your skills, this guide will equip you with the knowledge you need.

Essential Tools and Equipment for Soldering Wires

Having the right tools and equipment is vital for successful soldering. From selecting the best soldering iron to understanding the types of solder available, we’ll break down the essentials you’ll need to get started.

Choosing the Best Soldering Iron

When selecting a soldering iron, consider factors like power settings, tip size, and temperature control. A soldering iron with adjustable heat settings will give you more control over the soldering process, ensuring you can adapt to different types of connections.

For beginners, a basic soldering kit that includes a compact soldering iron, solder wire, and a small stand can be an excellent investment. As you progress, you may want to invest in more specialized tools, such as a soldering gun for larger projects or reflow ovens for surface mount soldering.

Understanding Different Types of Solder

Solder comes in various types, including lead-free and lead-based options. Lead solder offers excellent conductivity, while lead-free solder is preferred for health and environmental considerations. Make sure to choose the right solder for your project, which can vary depending on the materials being connected.

Essential Safety Equipment

Soldering can produce harmful fumes and involve hot equipment. It’s crucial to work in a well-ventilated area, use safety goggles to protect your eyes, and wear gloves if you’re handling hot components. Always have a fire extinguisher nearby, especially if you’re working with flammable materials.

Step-by-Step Process for Soldering Wires

With the essential tools in hand, it’s time to delve into the step-by-step process for soldering wires effectively. These basic soldering steps will lay the foundation for mastering this skill.

Preparing the Wires for Soldering

Begin by stripping the insulation off the ends of the wires you intend to solder. Use a wire stripper to expose around 1/4 inch of copper wire. Ensure that the wire ends are clean and free from oxidation or corrosion. Cleaning the wires with isopropyl alcohol can improve solder adherence.

Applying Solder Flux

Utilizing solder flux is essential for creating strong connections. Flux helps remove oxidation from the metal surfaces and promotes better solder flow. Apply a small amount of flux to the stripped wire ends before soldering.

Joining the Wires

Twist the wire ends together for stability. Next, apply the hot soldering iron to the connection and feed solder wire into the joint. The solder will flow into the gap, creating a solid connection. Ensure you do not use too much solder; a clean joint should appear shiny and smooth.

Advanced Soldering Techniques for Better Connections

Once you’ve mastered the basics, you can explore more advanced soldering techniques that can enhance your skills and improve your results.

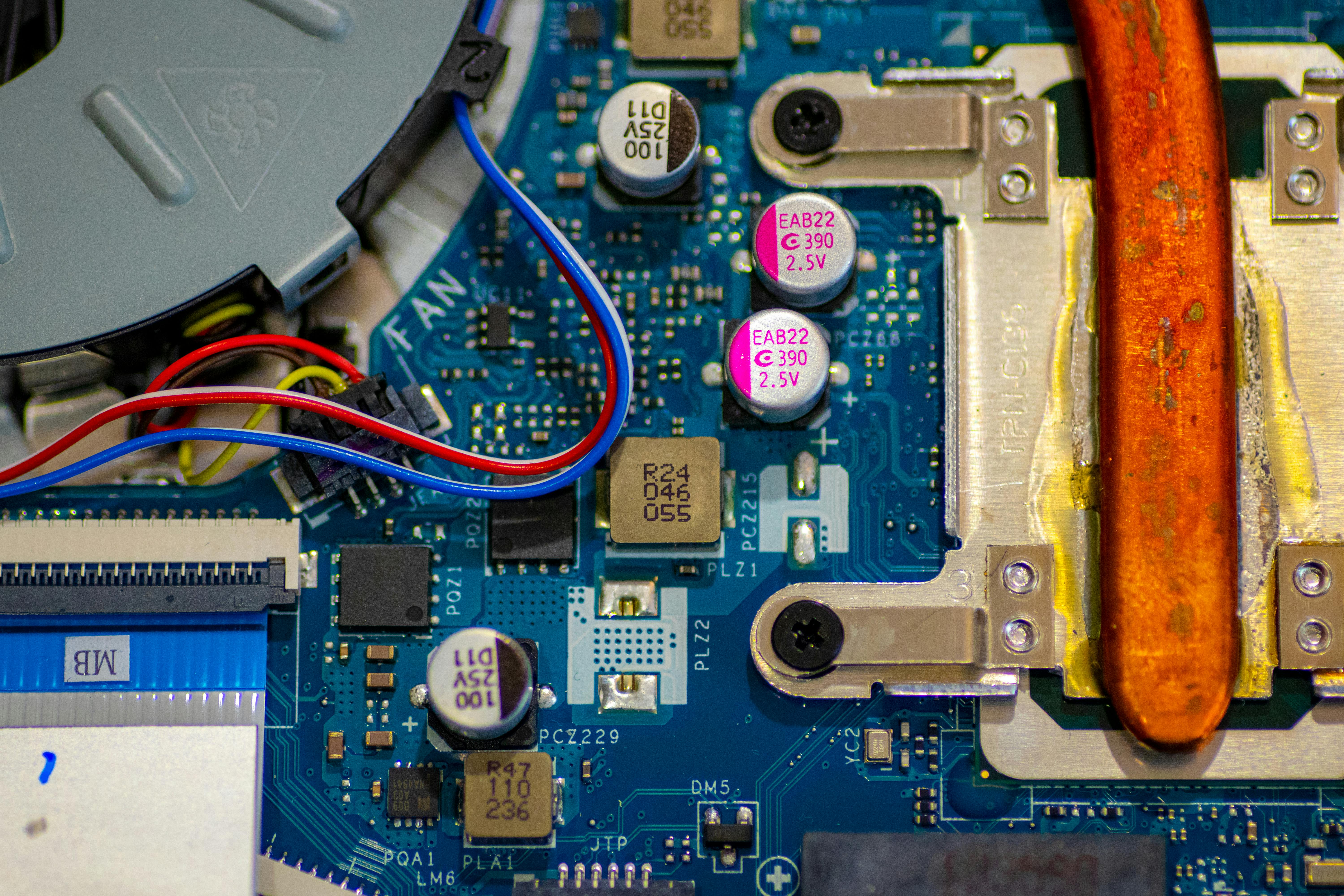

Soldering Surface Mount Components

Surface mount soldering requires precision but can be mastered with practice. Use solder paste and a hot air rework station for more complex circuit boards. This method helps to evenly distribute heat and solder.

Using Solder Wick for Desoldering

Every soldering enthusiast faces the occasional need to remove solder. Solder wick is a copper braid that absorbs excess solder when heated. Simply place the wick over the joint and apply the soldering iron. This technique is invaluable for correcting mistakes.

Understanding Soldering Wire Sizes

Different wire gauges require different soldering techniques. Understanding the relationship between wire size and solder will improve joint strength. For instance, larger wires may require higher temperature settings to properly melt the solder.

Common Soldering Mistakes and How to Avoid Them

Many beginners make common mistakes that can compromise their soldering projects. Identifying and avoiding these pitfalls can save time and frustration.

Overheating Components

Overheating can damage sensitive components, causing them to fail. Use a temperature-controlled soldering iron and work quickly to avoid heat damage to electronic parts.

Using Improper Soldering Techniques

Ensure that you are using the correct technique for the type of connection you’re making. For instance, applying solder directly to the tip of the soldering iron rather than the joint can lead to poorly made connections.

Soldering in a Poor Environment

Lighting, ventilation, and workspace organization matter. Ensure your workspace is well-lit and organized to make soldering easier and safer. Working in a cluttered or poorly ventilated area can increase the risk of accidents.

FAQs About Soldering Wires

Here are some common questions regarding soldering wires with their answers to help expand your understanding.

What is the best type of solder for beginners?

For beginners, rosin-core, lead-free solder is often recommended. It is easy to work with and provides good electrical conductivity without harmful fumes.

How can I improve my soldering skills?

Practice is key! Work on simple projects first, and gradually try more complex designs. Enrolling in a soldering class can also provide you with hands-on experience and valuable feedback.

What should I do if my solder doesn’t stick?

If your solder isn’t adhering properly, ensure the surfaces are clean and free of oxidation. Additionally, applying solder flux can significantly improve joint quality.

How can I troubleshoot common soldering issues?

Common soldering issues include cold solder joints and bridging. To troubleshoot, check your technique and ensure your workspace is tidy to avoid unintentional connections between solder joints.

Are there any safety precautions I should take when soldering?

Always work in a well-ventilated area, use safety goggles, and avoid touching the soldering iron when hot. Cleaning up your workspace and storing tools safely also contributes to a safer soldering experience.

By following the tips outlined in this soldering guide, you’ll be well on your way to mastering effective soldering techniques and creating reliable wire connections. Whether you’re tackling basic projects or diving into more advanced electronics work, having these skills will greatly benefit your soldering experience. For a detailed guide on related topics, check out our resourceful articles on soldering techniques and soldering projects for beginners.